Handling Products - Systemic Construction Kits

Two-Axis Cartesian Handlings in X-Z & X-Y configuration

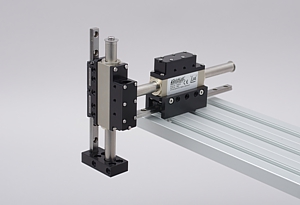

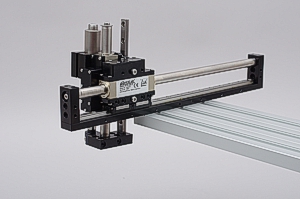

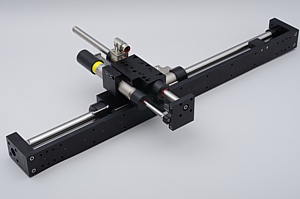

X-Z Pick&Place with Serial Kinematics

Our smallest and simplest two-axis handling systems

Performance:

- complied from our QuickLab® set

& expandable - max. cycles approx. 120 min-1

- working surface 160 x 160 mm² (X x Z)

- payload approx. 500 grams

- easy control with PLC

- motor cabels in requested lenghts

available on short-term

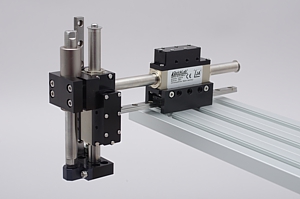

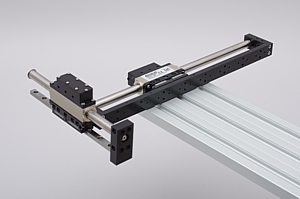

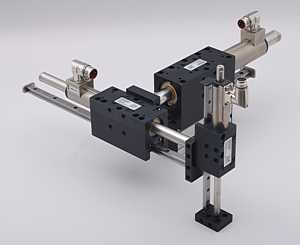

X-Z Pick&Place with Serial Kinematics

Very small two-axis handling systems

Performance:

- complied from our QuickLab® set

& expandable - max. cycles approx. 120 min-1

- working surface 160 x 160 mm² (X x Z)

- payload approx. 500 grams

- easy control with PLC

- motor cabels in requested lenghts

available on short-term - weight force compensation optinal

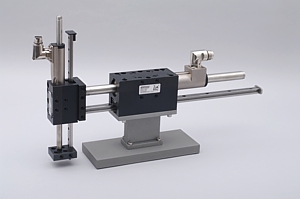

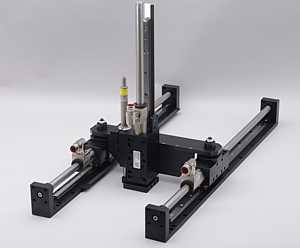

X-Z Portal with Serial Kinematics

Very small two-axis handling systems -

moving stator in X-axis

Performance:

- complied from our QuickLab® set

& expandable - max. cycles approx. 120 min-1

- working surface 220 x 160 mm² (X x Z)

- payload approx. 500 grams

- easy control with PLC

- motor cabels in requested lenghts

available on short-term - weight force compensation optinal

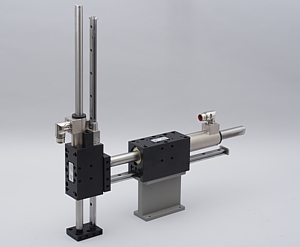

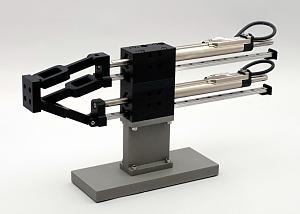

X-Y Portal with Serial Kinematics

Very small two-axis handling systems -

slider moving in X-axis

Performance:

- complied from our QuickLab® set

& expandable - max. cycles approx. 120 min-1

- working surface 220 x 160 mm² (X x Y)

- payload approx. 500 grams

- easy control with PLC

- motor cabels in requested lenghts

available on short-term - weight force compensation optinal

Two-Axis Cartesian Handlings in X-Z configuration

X-Z Pick&Place with Serial Kinematics

Fast, small two-axis handling systems

Top Price - Three Triple Nine!

Performance:

- EUR 3.999,-- per unit for the Pick&Place equipment displayed in the top right corner (console not included)

- What you see is what you get - included are the displayed P&P system, example circut layouts, emergency-stop concept, pre-parametered PP controller & parametric software

- complied from our HighDynamic® set

& expandable - max. cycles approx. 120 min-1

- work surface 60 x 60 mm² (X x Z)

- payload 500 grams

- easy control with SPS

- motor cabels in requested lenghts

available on short-term - cable chain with integrated motor cable optional

- weight force compensation optinal

Very fast, two-axis handling systems

Performance:

- freely configurable with standard components

from the HighDynamic® set - easy assembly with 4 screws, possible

without adaptor - cycles up to approx. 250 min-1

- max. work surface approx. 1.690 x 480 mm² (X x Z)

- small to medium payloads

- easy controll

- C-axis optional

- motor cabels in requested lenghts

available on short-term - cable chain optional

- weight force compensation optinal up to 350 mm stroke

- pneumatic clamping unit optional (2nd photo)

- wiper for rough environments optional (3rd photo)

Applications:

|

|

X-U-Z Gantry Portal

Fast, two-axis portal

Performance:

- compiled with components from our

HighDynamic® set - cycles up to approx. 120 min-1

- max. work space approx. 1.500 x 280 mm³

- X & U axis in gantry configuration

- pivoted crossbar for connection of X & U-axis

- medium payloads

- easy control

- C-axis optional

- weight force compensation optional

Applications:

|

|

Two-Axis Cartesian Handlings in Z-X configuration

Z-X Pick&Place with Serial Kinematics

Very small & fast, two-axis handling system with large X-stroke & very flat X-arm

Performance:

- compiled with components from our QuickLab® set

- cycles up to approx. 120 min-1

- max. work surface approx. 220 x 100 mm² (X x Z)

- small payloads

- arm of X-axis only 20 mm high

- no moving drive cables

- weight force compensation

- easy control

Applications:

|

|

Fast, two-axis handling system with large X-stroke & very flat X-arm

Performance:

- compiled with components from our HighDynamic® set

- cycles up to approx. 200 min-1

- max. work surface approx. 500 x 100 mm² (X x Z)

- medium payloads

- arm of X-axis only 40 mm high

- no moving drive cables

- weight force compensation

- easy control

- wiper for rough environments optional

Applications:

|

|

Two-Axis Handlings with Parallel Kinematics

X-Z Pick&Place with ParaPicker® Technology

Tow-axis handling systems with very fast Z-stroke

Performance:

- compiled with components from our HighDynamic® set

- cycles tp to approx.. 280 min-1

- max. work surface approx. 280 x 150 mm² (X x Z)

- small payloads

- very fast Z-stroke

- great force in X-direction

- no moving drive cables

- wiper for rough environments optinal

Applications:

|

|

Handlings with 3 or more Cartesian Axes

X-Y-Z Muli-Axis Handlings with Serial Kinematics

Tripple-axis handling systems

Performance:

- compiled with components from our HighDynamic® set

- easy assembly with 4 screws, possible

without adaptor - cycles up to approx. 80 min-1

- max. work space approx. 330 x 280 x 180 mm³

- small to medium payloads

- easy control

- C-axis optional

- weight force compensation optinal

- wiper for rough environments optional

- low overall cost

Applications:

|

|

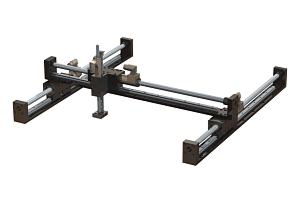

X-U-Y-Z Gantry

Three-axis handlings

Performance:

- compiled with components from our HighDynamic® set

- cycles up to approx. 80 min-1

- max. work space approx. 1.500 x 1.300 x 280 mm³

- medium payloads

- easy control

- C-axis optional

- weight force compensation optinal

Applications:

|

|

Multi-Axis Handlings with Parallel Kinematics

X-Y-Z-C Robot with ParaPicker® Technology

3 or 4-axis Handling Systems

Performance:

- compiled with components from our HighDynamic® set

- cycles up to approx. 400 min-1

- max. work space approx. 500 x 500 x 280 mm³

- small payloads

- very fast X-Y-stroke

- great force in Z direction

- C-axis rotating infinitely

- pneumatic brake optional

Applications:

|

|

Linear-Rotary Handlings

Z-C Linear-Rotary Modules

Fast, rotary-stroke handlings

Performance:

- compiled with components from our HighDynamic® & ForTorque® set

- Z-stroke up to 330 mm

- C-axis rotating infinitely

- free angular positioning

- weight force compensation optional

Applications:

|

|

Linear-Swiveling-Rotary Handlings

Linear-Swiveling-Rotary Combinations

Fast, linear-swiveling-rotary combinations

Characteristics:

- ForTorque® rotary modules combined with HighDynamic® linear motor modules

- adaptor AD13 & AD15 for HM01, FT01-25 & FT01-45

Fast Handlings for Force-Stroke Monitored Processes

Tactile Positioning - Sensitive Actuators

Applications:

- mating of shaft-to-hub connection

- mating of locking rings on shafts

- mating of locking bolts on shafts

- mating of O-rings on shafts

- testing of springs

- mating of electronic parts

- mating of electronic boards in casing

- testing of electronic components

- testing of connectors

- vibration testing

HighDynamic® Modules with Load Transducer

Load transducer with adaptor AD01

Characteristics:

- compiled with components from our HighDynamic® set

- suitable for DMS force transducer U2B from HBM

- for HighDynamic® modules HM01-37 & HM01-48

Actuator Modules with Load Transducer & Vacuum

Characteristics for a custom example:

- dynamic push/pull testing

- max. stroke 90 mm

- max. push/pull force 1.100 N

- continuous push/pull force 510 N

- load sensor for exact force measurements & regulations

- stroke sensor integrated into motor

Handling Products - Download Center

VideoClips

> #32 - X-Z high-speed Pick&Place

> #49 - Z-X high-speed Pick&Place

> #26 - ParaPicker® PP02 demonstration

Copyrights

Our texts, images, graphics, videos and sounds are subject to the protection of international copyright laws! For trademarks of others, see our copyrights.