LinTorque® Linear Rotary Modules - Systemic Construction Kit

Overview

LinTorque® stands for a systemic combination of high-dynamic linear motor modules and advancing rotary servo modules.

LinTorque® linear rotary modules are mechanically modular combinations from our QuickLab®, HighDynamic® and ForTorque® series. Due to cross-product modularity, several combinations of products are possible. The shown pictures only represent sample solutions.

Applications:

|

|

LinTorque® Linear Rotary Modules

General characteristics:

- modular construction from a combination of our QuickLab®, HighDynamic® & ForTorque® product ranges

- attractive price

- extensive range of fixtures & adaptors

Characteristics vertical axis:

- linear motor drive

- stoke up to 330 mm

- peak force up to 1.024 N

- continuous force up to 203 N / 354 N with forced cooling

- positioning repeatability +/- 0,05 mm

- linearity positioning sensor +/- 0,1 %

Characteristics rotary axis:

- AC servo motor with gearbox

- peak torque up to 4,0 Nm

- rotation angle repeatability < 20 angular minutes

- max. torque up to 400 RPM

- endless rotation angle

- large process forces & process moments on output bearing

- torque measurement through current

- suitable for large external inertia loads

Options:

- MagSpring® extension for weight force compensation

- pneumatic brake

- adaptor for afag, Schunk & Sommer grippers

- fluid passages

Linear Rotary Modules - Systemic Construction Kit

Z-C linear rotary modules from the mechatronics & specials construction kit

Characteristics:

- ForTorque® rotary module FT01-2043 combined with QuickLab® QM02-2070 linear motor module

- AD62 adaptor

- MagSpring® for weight force compensation with adaptors

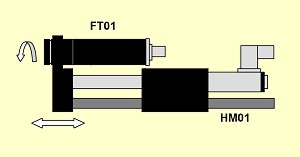

Linear Rotary Modules - Systemic Construction Kit

Z-C linear rotary modules from the mechatronics & specials construction kit

Characteristics:

- ForTorque® rotary module FT01 combined with HighDynamic® HM01 linear motor module

- AD12 adaptor

- MagSpring® for weight force compensation with optional adaptor

Linear Rotary Modules - Systemic Construction Kit

Z-A linear rotary modules from the mechatronics & specials construction kit

Characteristics:

- ForTorque® rotary module FT01 combined with HighDynamic® HM01 linear motor module

- AD13 adaptor

- MagSpring® for weight force compensation with optional adaptor

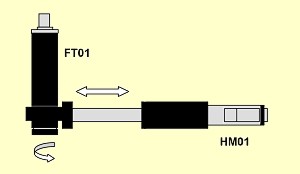

Linear Rotary Modules - Systemic Construction Kit

Z-C linear rotary modules from the mechatronics & specials construction kit

Characteristics:

- ForTorque® rotary module FT01 combined with HighDynamic® HM01 linear motor module

- AD13 adaptor

- MagSpring® for weight force compensation with optional adaptor

Linear Rotary Modules - Systemic Construction Kit

Z-C linear rotary modules from the mechatronics & specials construction kit with weight force compensation

Characteristics:

- ForTorque® rotary module FT01 combined with HighDynamic® HM01 linear motor module

- AD12 adaptor

- MagSpring® for weight force compensation combined

- AD03 & AD04 adaptors

Linear Rotary Combinations - Systemic Construction Kit

Z-A-B linear swivelling-rotary combinations from the mechatronics & specials construction kit

Characteristics:

- several ForTorque® rotary modules combined with HighDynamic® linear motor modules

- AD13 & AD16 for HM01, FT01-25 & FT01-45 adaptors

LinTorque® Positioning Controller

For our LinTorque® linear swivelling-rotary modules, we use controllers out of the LinMot® range.

Characteristics:

- 24 VDC logic supply

- 48 - 72 VDC power supply

- 8 - 32 A output current

- selection of positioning tasks with freely definable motion profiles over I/O’s or fieldbusses

- oscillating motion

- analog position target 0 - 10 V

- pulse & direction inputs

- master-booster or gantry mode

- master-encoder synchronization

- streaming mode

- input for external high-resolution positioning sensor

- variable homing modes

- Safe Torque Off (STO)

- fieldbusses EtherCAT, POWERLINK, PROFINET, SERCOS III, TCP/IP, Profibus-DP, CANOpen, DeviceNet

- licence-free configuration tool LinMot-Talk

- controller configuration according to motor and application data

LinTorque® - Download Center

Brochures & Data Sheets

> LinTorque® overview

> HighDynamic® HM01 data sheet

> HighDynamic® options data sheet

> ForTorque® FT01 data sheet

> ForTorque® options data sheet

VideoClips

> #39 - LinTorque® demonstration with FT01-4550 rotary module

> #43 - LinTorque® & ForTorque® Ddemonstration with FT01-2520

> #47 - LinTorque® screwing demonstration with FT01-4550 rotary module

Installation, Maintenance & EC Guidelines

> Installation guide, maintenance instructions & declaration of conformity - HM01

> Installation guide, maintenance instructions & declaration of conformity - FT01

> Safety data sheet FDA grease for linear motors LU02

> Safety data sheet FDA grease for linear guides

Copyrights

Our texts, images, graphics, videos and sounds are subject to the protection of international copyright laws! For trademarks of others, see our copyrights.