QuickShaft®

Overview

QuickShaft® stands for high-dynamic, miniaturized, tubular linear direct drives with ironless technology.

They are the ideal drives for high-dynamic applications at small strokes and lower forces. We offer ready-to-use guide systems, positioning controllers, customized motor cables and supply units with the components.

For easy integration into customer applications, we deliver examples of circut drawings, accordingly ready configurated positiong controllers, emergency-stop concepts, as well as licence-free software tools.

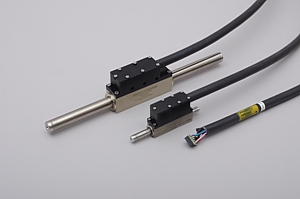

QuickShaft® Servo Drives

QuickShaft® are directly driven, miniature, tubular servo drives with ironless technology. With an excellent performance/volume ratio, QuickShaft® drives are especially suited for applications with positiong taskes in the tightes of spaces.

Characteristics:

- tubular, dynamic electromagnetic direct drives with ironless technology

- integrated, incremental measurement system, sensing of the drive magnets

- one-cable technology

- integrated plain bearing

- positioning repeatability +/- 0,05 mm

- peak force up to 28 N

- max. stroke 120 mm

- protection class IP20

- long operational life

Options:

- M12 connector type 'B'

- direct cable outlet type 'Z', cables for use with cable chains up to 30 m

- cable sets ready to use

Faulhaber® Positioning Controller

In simple and low dynamic applications we preferably use controllers out of the Faulhaber® range in combination with our QuickShaft® motor series.

Characteristics:

- 24 VDC logic supply

- 24 VDC or 48 VDC power supply

- 2 - 5 A output current

- analog position target 0 - 10 V

- fieldbusses EtherCAT, CANOpen, RS232

- licence-free configuration tool MotionManager

- controller configuration according to motor and application data

LinMot® Positioning Controller

In high dynamic applications and if fieldbusses are required we preferably use controllers out of the LinMot® range in combination with our QuickShaft® motor series.

Characteristics:

- 24 VDC logik supply

- 48 - 72 VDC power supply

- 8 - 32 A output current

- selection of positioning tasks with freely definable motion profiles over I/O’s or fieldbusses

- oscillating motion

- analog position target 0 - 10 V

- pulse & direction inputs

- master-booster or gantry mode

- master-encoder synchronization

- streaming mode

- input for external high-resolution positioning sensor

- variable homing modes

- Safe Torque Off (STO)

- fieldbusses EtherCAT, POWERLINK, PROFINET, SERCOS III, TCP/IP, Profibus-DP, CANOpen, DeviceNet

- licence-free configuration tool LinMot-Talk

- controller configuration according to motor and application data

Power Supplies & Customized Motor Cables

We manufacture power supplies suitable for all LinMot® controllers. Customized, ready-to-use motor cables complete the delivery program.

Characteristics:

NT01 - power supply series

- transformer power supplies up to 450 W continuous output power

- single or tripple mains input 230 VAC or 400 VAC

- largly dimensioned output DC bus capacitor

NS01 - power supply series

- switched power supplies up to 3 kW constant output power

- suitable for worldwide mains

- single-phase mains input with active harmonics filtering

- all internal components with UL approbation

Customized cables

- standard cables

- trailing chain cables

- robotic cables

Services & Engineering

Through many years of experience with appilcations of direct drives, we can offer extensive services, as well as superb and extremely prompt engineering.

- cinematics

- selection of drives

- tranings

- mechanical and electrical engineering

- configuration, programming & fiedbus applications

- implementation & optimization

- complete mechatronics solutions

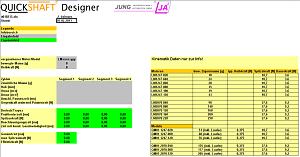

QuickShaft® - Download Center

Brochures & Data Sheets

> QuickDynamic® & QuickShaft® overview

> QuickShaft® linear motor data sheet

VideoClips

> #29 - QuickDynamic® module demonstration

Copyrights

Our texts, images, graphics, videos and sounds are subject to the protection of international copyright laws! For trademarks of others, see our copyrights.